What is touch alignment and how does it work?

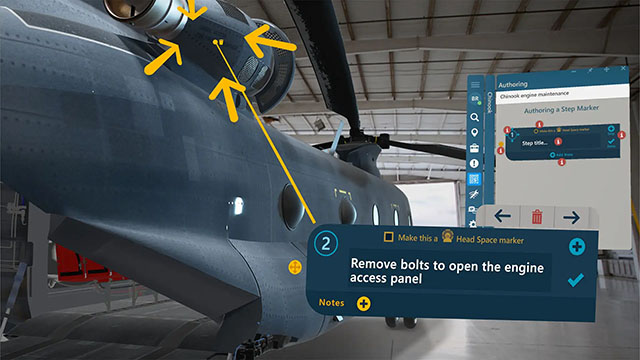

Touch Alignment eliminates the need for Manifest users to place printed tags on equipment to anchor AR content or identify equipment. Content creators are prompted to select three reference points on a piece of equipment and touch them. Using a combination of the device camera and hand tracking, Manifest saves the coordinates of each point, then prompts the author to select placement of a virtual tag. This digital tag serves as the anchor point for all spatially anchored content and will be replicated for all assets of that same class so that content can be accurately and consistently located across equipment.

For detailed information on setting up Touch Alignment, please reference the user guide.

When should I use touch alignment?

Touch alignment was specifically designed for the following uses:

- Rugged environments where a printed tag cannot withstand wear and tear and risk damage

- Industrial environments where cleaning or sanitizing protocols require removal of a printed tag (e.g. bioscience or pharmaceutical)

- Industries where regulations prohibit placing physically printed tags on equipment (e.g. aircraft maintenance)

- Generally, any environment where placing a physical tag on equipment or vehicle is impractical

Which Manifest platforms support Touch Alignment?

Currently Touch Alignment is supported on Manifest for HoloLens 2. Support for additional platforms is being researched and explored. Please contact the Taqtile team if you need support on a specific device.

My Manifest procedures were authored using a printed asset tag, how do I replace this with Touch Alignment?

To recalibrate procedures to anchor content using Touch Alignment or to replace your printed asset tags, you will need to set up touch alignment for the asset class. If printed tags are in use, it is CRITICAL that the printed tag is scanned as part of Touch Alignment set up. This will help ensure accuracy of existing spatially authored content. Reference step 8 in the Touch Alignment set up guide.

Can I use Touch Alignment in one location and printed tags in another?

Touch alignment is currently only supported on HoloLens 2. If your implementation leverages only this platform, you can use a combination of both printed tags and touch alignment.

If using Manifest across multiple platforms, and your implementation relies on spatially authored content, continued use of a printed tag is required.

How do workers get to work using Touch Alignment?

Existing printed Asset Tags provide several indicators for Manifest operators including:

- Specific Asset details scanning a printed tag quickly identifies the asset in Manifest and displays a window with the asset details including Templates and Jobs specific to the equipment

- Registration confirmation scanning a printed tag provides confirmation that the specific equipment has been configured and registered within Manifest

- Call to action scanning a printed tag provides operators with an initial action to quickly begin work

Consider your current Manifest implementation and operational best practices when implementing touch alignment to best assess how to modify existing processes to support worker adoption. Consider the following:

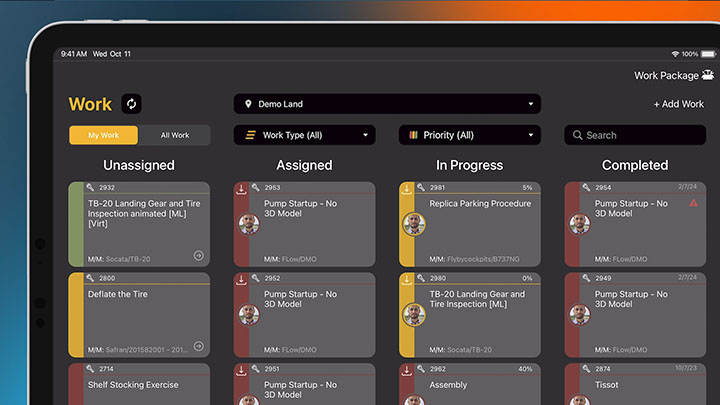

- How will workers know a piece of equipment is registered in Manifest?

- How do workers know how to locate and identify a piece of equipment in Manifest?

To enable workers to get to work quickly using Touch Alignment, Manifest administrators and Authors can do the following:

- Consider indicators on equipment to signal that the equipment is registered in Manifest (or address with training) so that workers are not searching for equipment that is not registered

- Train operators to quickly locate an Asset in Manifest using search feature using the following tips for guidance:

- Configure Assets in Manifest using text already printed on machines or equipment – such as serial numbers, or internal id numbers

- Train workers to use Search with a new feature, text capture to locate specific Assets. Using the device camera, workers can take a photo of a serial number or internal ID number and Manifest will automatically digitize the text to be used in the search

- Once the worker has located the Asset, workers can use the Touch Alignment feature to quickly get to work

- Additional guidance can be found in the tag placement using touch alignment section of the user guide

Tips from the Experts

- Before setting up Touch Alignment, ensure your HoloLens 2 device is calibrated for the Author that will be doing the set-up

- When creating alignment points, consider the following:

- Alignment points should be on stationary parts of equipment that never moves

- Alignment points should be placed on parts of equipment that are easy to identify, for example near a corner, bolt, or some unique identifier. If placing near a corner, leave a small border

- Points should be placed far apart to improve accuracy

- Points should be positioned in the line of sight of workers so consider the varying height of all workers and select a spot that will be suitable for everyone

- Avoid placing points on a flat surface that requires the device camera and workers gaze to be directly pointed down. Optimal placement is vertically with the device camera facing forward

- Avoid placing Touch Alignment reference points in locations where there is a lot of direct light. When an environment is too bright, the device cameras get saturated and replicating reference points can be inconsistent

- When authoring and operating with Touch Alignment, ensure device cameras are pointing at equipment head on and that the users hand is positioned in the cameras line of sight. If the device’s hand tracking cannot register a specific point, Manifest will restart the countdown timer. This is a good indicator that the user’s hand isn’t positioned in relation to the camera. Replace hand position and try again.

- If workers are using Manifest and HoloLens 2 with safety gloves, they should not be black. Black gloves make hands difficult to recognize and hinder the devices ability to track hands